2 Feature Analysis: Off-site Transfers to Disposal in North America, 2014–2018

2.5 Sustainable Production and Alternatives to the Generation and Disposal of Industrial Waste

2.5.4 Examples of sustainable practices within North American industry

North American industrial facilities and sectors have implemented a wide variety of strategies and actions, which can be grouped into the categories presented below, with the objective of increasing the sustainability of their operations. This section describes the efforts that have been undertaken by companies representing the top industry sectors for reported off-site transfers to disposal and featured in the data analyses in section 2.4.

1. Global Commitments

a. Alignment with Agenda 2030 and SDG 12

Through their corporate sustainability reports and other means, some North American companies demonstrate their commitment and progress towards the SDGs outlined in Agenda 2030, including SDG 12: Responsible Consumption and Production.

2. Regulation

a. Environmentally sound management of regulated substances

The environmentally sound management of regulated or controlled substances may involve a variety of activities aimed at increasing efficient, safe, and orderly operations, including the hiring of qualified personnel and regular related training; periodic inspections to ensure compliance with regulations and standards for the handling and disposal of substances; and so on.

3. Process Efficiencies

a. Best Available Techniques and Best Environmental Practices

A key circular economy strategy relates to the exchange and adoption (both nationally and internationally) of the best available techniques (BAT) and the best environmental practices (BEP) specific to an industry or process, which evolve over time in light of technological advances, changes in science, knowledge and understanding, and other factors (UNEP 2017).

b. Process and equipment modifications

This refers to improvements to industrial processes and/or equipment, including implementation of new processes that produce less waste; the reuse of chemicals; and technological changes affecting the synthesis, formulation, fabrication and assembly, and surface treatment such as cleaning, degreasing, surface preparation, and finishing.

c. Substitution of raw materials or integration of recycled materials

The International Chemicals Secretariat Marketplace (ChemSec Marketplace) is a website that provides information on the substitution of hazardous chemicals in products. It features announcements of safer alternatives from manufacturers and serves as a platform where downstream users can request safer alternatives for their industrial needs.[86]

4. Administrative Processes

a. Optimizing logistical processes

Optimizing logistical processes results in several benefits—for instance, minimal downtime, delays, and warehouse usage; identification of best transport and distribution channels; implementation of management indicators and automated systems for waste storage, transport, and disposal; and others.

b. Development of green value chains linking suppliers with customers

Synergies and alliances are promoted between companies that supply raw materials and services and their client companies.

c. Corporate Social and Environmental Sustainability reports

Corporate Social Responsibility (CSR) reports facilitate the promotion of transparency about a company’s role in the community, its considerations of the environmental and social impacts of its operations, and the non-financial factors that influence its business decisions. CSR reports also help companies evaluate risk and facilitate their participation in the stock market.

d. Certification of management and reporting systems

Several management and reporting systems facilitate company operations and fulfilment of their environmental responsibilities, including:

- ISO management systems: The International Standards Organization (ISO) defines systems certification as a third-party declaration that an organization’s management system meets the requirements established in a reference standard. Relevant ISO standards for North American industrial facilities and sectors include: a) ISO 9001: Quality Management Systems; b) ISO 14001: Environmental Management Systems; c) ISO 28001: Security Management Systems for Supply Chains.[87]

- Socially responsible company: A company complies with and integrates into its organizational culture a set of standards and principles based on recognized social, economic, and environmental values. While not mandatory, many companies seek such certification because of the favorable image and competitive advantage it generates.

- Clean Industry certification (Certificación en Industria Limpia, Mexico): This program supports the integration of an environmental management system to enable regulatory compliance that extends to a company’s personnel, processes, and equipment. This compliance is evaluated in a comprehensive, systematic, objective, and documented manner.[88]

- Environmental Excellence Award (Reconocimiento a la Excelencia Ambiental, Mexico): This is the highest distinction awarded by the Mexican Government, through the federal environmental protection agency (Procuraduría Federal de Protección al Ambiente—Profepa), to companies that have demonstrated a high level of environmental commitment, compliance, and performance and have been certified by the National Environmental Audit Program (Programa Nacional de Auditoría Ambiental—PNAA).[89]

- Green Chemistry Challenge Award (United States): EPA’s Green Chemistry Challenge Awards, in partnership with the Green Chemistry Institute and other stakeholders from industry, academia, and government, promote the environmental and economic benefits of developing and using green chemistry practices. These annual awards recognize technologies that incorporate the principles of green chemistry in the product life cycle (i.e., in the design, manufacture, use and disposal of chemical products).[90]

- Safer Choice program (United States): This EPA program helps consumers and commercial buyers identify and select products with safer chemical ingredients, without sacrificing quality or performance. The program provides information of public interest and a list of safe chemical substances.[91]

- Regional pollution prevention (“P2”) recognition program (United States): This annual program recognizes company successes in pollution prevention and encourages other to consider similar approaches. It has proven to be a successful, non-regulatory approach to conserving energy and water, reducing toxic materials and emissions, recycling, and saving money for the states of Iowa, Kansas, Missouri, and Nebraska.[92]

- SDG Leadership Awards (Canada): These awards, sponsored by Canada’s Global Compact Network, recognize exceptional efforts by the private, academic, and non-profit sectors to integrate and advance action towards the UN SDGs.[93]

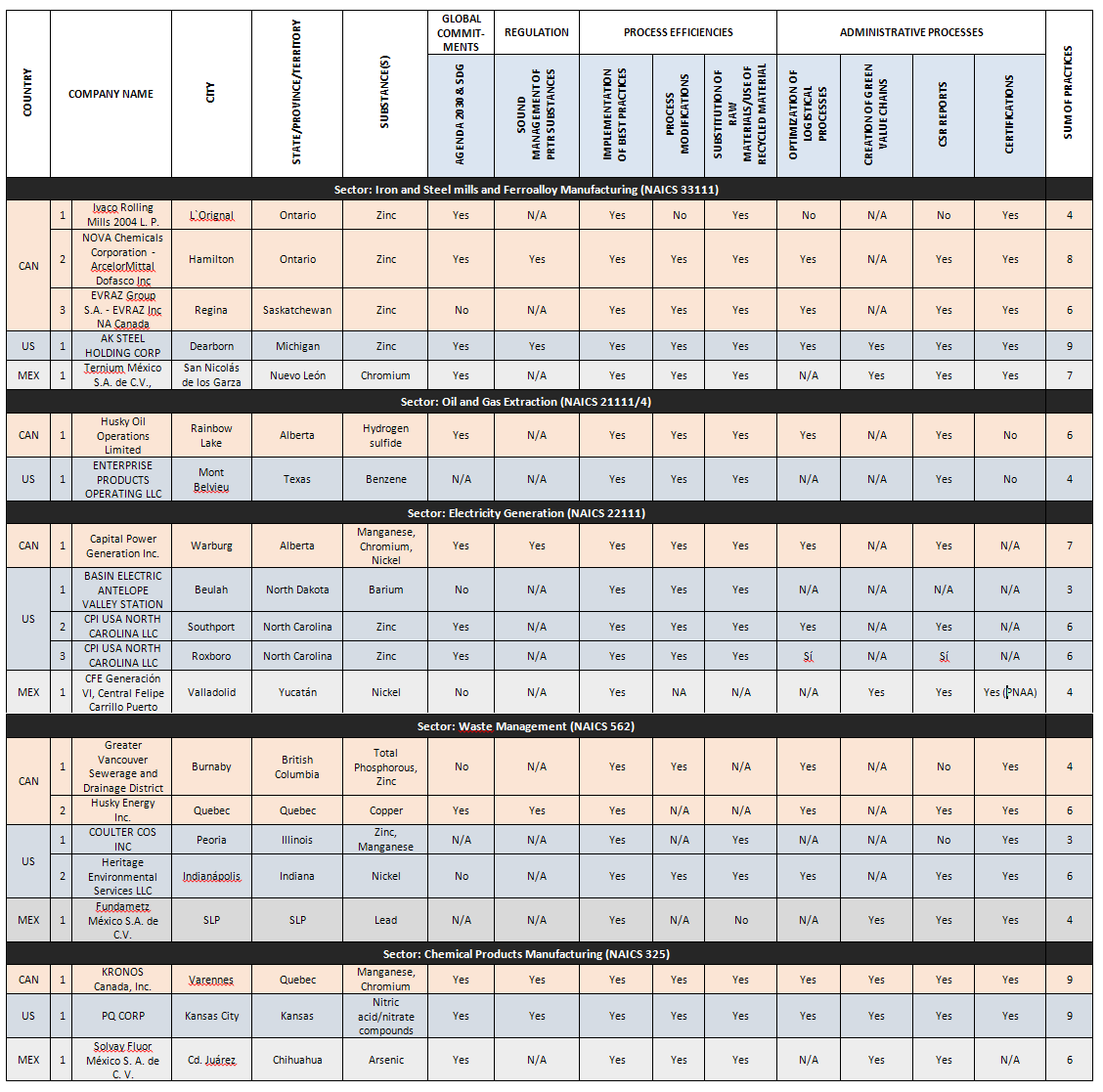

Table 44 presents a sample of companies, representing the leading industry sectors in the region for reported transfers to disposal between 2014 and 2018, that have embraced strategies and actions aimed at increasing the sustainability of their operations. These companies are identified by sector and location, and by one or more representative substance for which they have implemented sustainable practices with the objective of minimizing the generation of waste and/or reducing their releases and transfers.

The table shows that each of these companies has implemented practices in at least three of the above-listed sub-categories, targeting those substances transferred to disposal in largest proportions (e.g., metal compounds such as zinc, chromium, and manganese; hydrogen sulfide; nitric acid/nitrate compounds).

It also shows that:

- 80% of these companies have replaced raw materials and/or integrated recycled raw materials into their processes

- 76% have made process changes

- 64% have optimized their logistical processes

- 64% have received certifications related to quality management systems

- 32% have participated in the creation of green value chains.

[86] ChemSec Market Place, “Future-proof your business: Find safer alternatives to hazardous chemicals”, International Chemicals Secretariat.

[87] ISO, Conformity Assessment: Certification, International Organization for Standardization.

[88] Tramiteo México, “Certificado de industria limpia”.

[89] Profepa, Programa Nacional de Auditoría Ambiental, Procuraduría Federal de Protección al Ambiente, Gobierno de México.

[90] EPA, Information About the Green Chemistry Challenge.

[91] EPA, Safer Choice.

[92] EPA, P2 Awards, EPA Region 7 Pollution Prevention Awards (Iowa, Kansas, Missouri & Nebraska)

[93] Global Compact Network Canada, 2019 SDG Leadership Awards.